What motor type is the most durable and quiet for automatic doors?

Automatic door motors play a decisive role in durability and smooth operation, which is why users always want to know which motor delivers the best stability and suits long-term use. This article explains each motor technology clearly to help you choose the most optimal solution.

1. Overview of automatic door motors and key criteria for durability and smoothness

Motor systems are the main driving force behind automatic doors, enabling smooth movement and directly influencing lifespan and user experience. Understanding their structure and evaluation criteria helps you choose the right motor for each project’s operating demands.

1.1 What is an automatic door motor? Main components

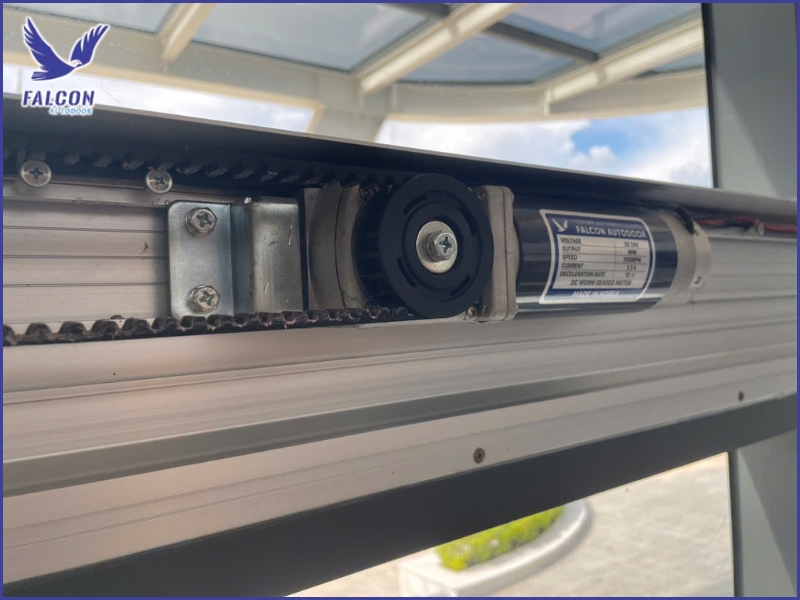

An automatic door motor includes the driving engine, the central controller, the belt system, the guide rail and the limit sensors. These components work together to deliver smooth motion, stable operation and safe performance throughout daily use.

1.2 Factors that determine motor durability

Motor durability depends on engine technology, material quality, heat dissipation capacity and dust- and moisture-resistant design. A motor built with solid components and engineered to handle high temperatures will maintain long-term stability even under continuous operation.

1.3 Criteria for evaluating motor quietness

A quiet motor has low vibration, minimal noise and operates with high-quality belts to reduce friction. When paired with an optimized transmission system and an intelligent controller, the door opens and closes softly without jerking and maintains stable noise levels over time.

2. Brushless motors (BLDC) - The most durable and quiet motor technology today

Brushless motors are considered the most optimal choice thanks to their stable performance, minimal wear and exceptionally quiet operation. This technology is widely used in modern automatic doors for both large projects and spaces that require quiet operation.

2.1 Brushless technology and why it extends lifespan

Brushless motors eliminate friction between the carbon brush and rotor, reducing wear, heat buildup and performance loss. Their construction allows longer lifespan, fewer minor failures and stable operation even during heavy and continuous usage. This makes them ideal for locations demanding long hours of operation without interruption.

2.2 Quiet performance and anti-wear capability

Because they operate without direct contact and without spark generation, brushless motors run with minimal noise. Low vibration and stable torque help the door move smoothly without jerking, even after years of operation. Their resistance to mechanical wear ensures consistent performance throughout the system’s lifespan.

2.3 Which projects are suitable for brushless motors?

Brushless motors suit shopping malls, hospitals, office towers, hotels and locations that require a professional appearance with extremely quiet operation. High-traffic areas should also use this technology to ensure durability and minimize long-term maintenance costs.

3. Traditional DC motors - Affordable and stable for common applications

Traditional DC motors remain popular thanks to their reasonable cost and reliable performance in many residential and commercial settings. While they are not as durable or quiet as brushless types, their simplicity and ease of maintenance make them a practical mid-range solution.

3.1 Advantages of DC motors

DC motors have lower upfront cost and widely available replacement parts, allowing quick repair without disrupting operation. Their simple construction also makes routine maintenance easier, which appeals to users needing budget-friendly installations.

3.2 Limitations compared with brushless motors

Because DC motors use carbon brushes that create direct friction, they typically generate more noise and have shorter lifespan than brushless motors. As the brushes wear out over time, maintenance becomes more frequent and the door may lose smoothness during operation.

3.3 Which projects are suitable for standard DC motors?

DC motors fit residential houses, small shops, small offices and projects with moderate usage frequency. They balance performance and cost, especially for installations that require quick deployment and do not demand ultra-quiet operation.

4. Additional factors that affect quietness besides the motor itself

The quietness of an automatic door depends not only on the motor but also on the belt system, guide rail precision, controller quality and installation technique. When these elements work in harmony, the door operates smoothly with minimal noise and vibration over time.

4.1 Belt quality and guide rail precision

Belts made from high-grade rubber or elastic materials help reduce vibration and create stable motion during opening and closing. Precisely machined guide rails allow rollers to travel smoothly without noise, supporting the motor’s performance and prolonging system durability.

4.2 Controller technology and speed calibration

Modern controllers can learn travel distance, self-adjust speed and fine-tune torque to eliminate sudden jerks. When the controller is stable, the door movement becomes gentle and consistent even in high-frequency environments or locations with temperature variations.

4.3 Installation technique and routine maintenance

Incorrect installation may cause the door to misalign, drag on the rail or create friction that increases noise. Proper calibration and scheduled maintenance help remove dust buildup, adjust belt tension and keep the motor running quietly with extended lifespan.

5. Which motor should you choose? Recommendations based on real needs

Choosing the right motor depends on usage frequency, priority on quietness, durability expectations and budget. When you identify actual operating needs, selecting the most suitable motor becomes simple and cost-efficient.

5.1 Large projects with high traffic

Areas such as shopping malls, hospitals, hotels, office towers or constantly active entrances should use brushless motors to ensure long-term silent performance and uninterrupted operation. This technology provides consistent efficiency without frequent maintenance.

5.2 Homes, retail shops and small offices

For locations with moderate usage, traditional DC motors meet everyday needs effectively. Their reasonable cost, easy replacement parts and simple maintenance help control budget while maintaining operational stability.

5.3 Projects requiring absolute quietness

Places like clinics, spas, premium hotels or offices that require a calm environment should use brushless motors combined with high-quality belts to minimize vibration. This ensures smooth, silent movement that does not disturb surrounding spaces.

Choosing the right automatic door motor ensures smooth, durable and low-maintenance operation over the system’s lifetime. When you evaluate usage frequency and noise requirements precisely, selecting the best motor for your project becomes straightforward.

If you need detailed advice or want help choosing the right motor configuration, contact Thuy Linh Long for on-site assessment, tailored recommendations and a clear quotation to keep your automatic door system running reliably in all conditions.

THUY LINH LONG SERVICES TRADING COMPANY LIMITED

DISTRIBUTOR

Address: 243D Vuon Lai Street, Phu Tho Hoa Ward, Tan Phu District,

Ho Chi Minh City, Vietnam.

Tel: +84 28 22497999

E-mail: cuatudong24h@gmail.com

SUPPLIER

KUM YANG MATERIALS CO.,LTD

Address: 124-60, Myeongdong-ro, Hallim-myeon,

Gimhae-si, Gyeongsangnam-do, 50851, Korea.

Tel: 82-55-345-8380